Precision Glass & Optic's glass fabrication capabilities include waterjet technology, laser engraving, annealing, CNC machining, drilling, optical grinding and polishing, diamond bandsawing, slicing, and scribing. Polishing capabilities (up to 36 inches diameter) typically reach flatnesses to λ/20, parallelism to 1 arc second, and tolerances to ±.0005 inches. Chemical and thermal glass tempering are also used to meet the most stringent part-strengthening requirements. PG&O provides custom fabrication from component level to sophisticated opto-mechanical design and assembly.

Annealing

The slow process of cooling glass to relieve internal stress is called annealing and it can greatly increase the durability of the glass part. PG&O's annealing capability removes the stress and strengthens glass components for myriad applications.

Blanchard Grinding

Rotary surface grinders, also called Blanchard grinders, removes unwanted material from one side of a part. Blanchard grinders have been the backbone of the optics industry for years and PG&O is able to provide tolerances that can be held to ±.002".

Centerless Grinding

If you require diameters tighter then ±.001", PG&O's centerless grinding is an ideal solution that provides tolerances that can be held to ±.0001".

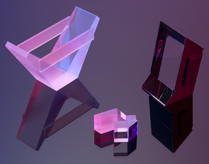

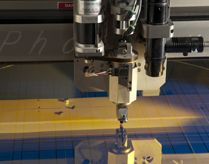

CNC Machining

Our state of the art CNC machining centers can generate parts with unusual shapes, holes, and grooves as large as 20" x 50". Tolerances can be held to ±.0005".

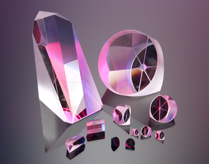

CP Grinding & Polishing

PG&O offers up to 20"Ø, flatness to λ/20, parallelism to 1 arc second and surface quality to 10/5 scratch/dig. Tolerances can be held to ±.0005".

Custom Component Assembly

PG&O provides customized assembly, from simple cementing of optics to advance opto-mechanical assemblies.

Double-Sided Grinding & Polishing

A cost-effective solution for polishing glass, PG&O provides double-sided grinding and polishing - tolerances can be held to ±.0005".

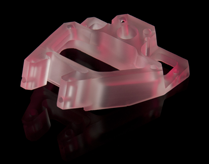

Drilling

PG&O can drill holes in material substrates from .030"Ø to 36"Ø with tolerances to ±.0005".

ID & OD Grinding

Utilizing PG&O's ID OD grinding equipment, we can generate diameters as large as 36"Ø and tolerances to ±.001".

Optical Grinding & Polishing

With our Strasbaugh grinding and polishing machines we can accommodate up to 36" Ø and can hold tolerances to ±.002".

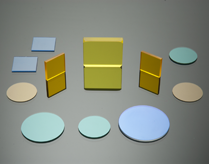

Optical Thin Film Coating

PG&O's advanced technology thin film coating facility includes a large 72" coating chamber. We are able to coat up to 4 substrates at 24"Ø's. Our precision thin film coatings operate in the spectral range from 250 nm out to 2.5 µm.

Sawing

We have diamond band sawing capabilities up to 18" thick on a variety of glass material substrates.

Scribing

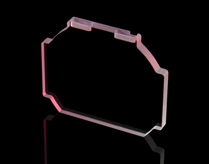

A computer-controlled glass scribing machine is ideal for cutting various shapes, from simple squares, rectangles, and circles, to complex shapes. At PG&O, tolerances can be held to ±.001".

Slicing

Slicing is a very cost-effective way to produce parts with high accuracies and excellent edge quality. At PG&O, tolerances can be held to ±.0005".

Thermal & Chemical Tempering

To strengthen your high quality glass parts, PG&O's thermal and chemical tempering service is available to meet your strictest requirements.

Back to Top